Case Study: Automating Inventory Management for Two Furniture Brands

Two of our clients, both growing furniture retailers, rely on a wide network of suppliers, many of whom send inventory updates via email in spreadsheet format. With large and frequently changing catalogs, both brands struggled to keep their online listings accurate and up to date.

Background & Challenge

Video Walkthrough

What They Wanted — and How We Got Them There

-

Their Goal

-

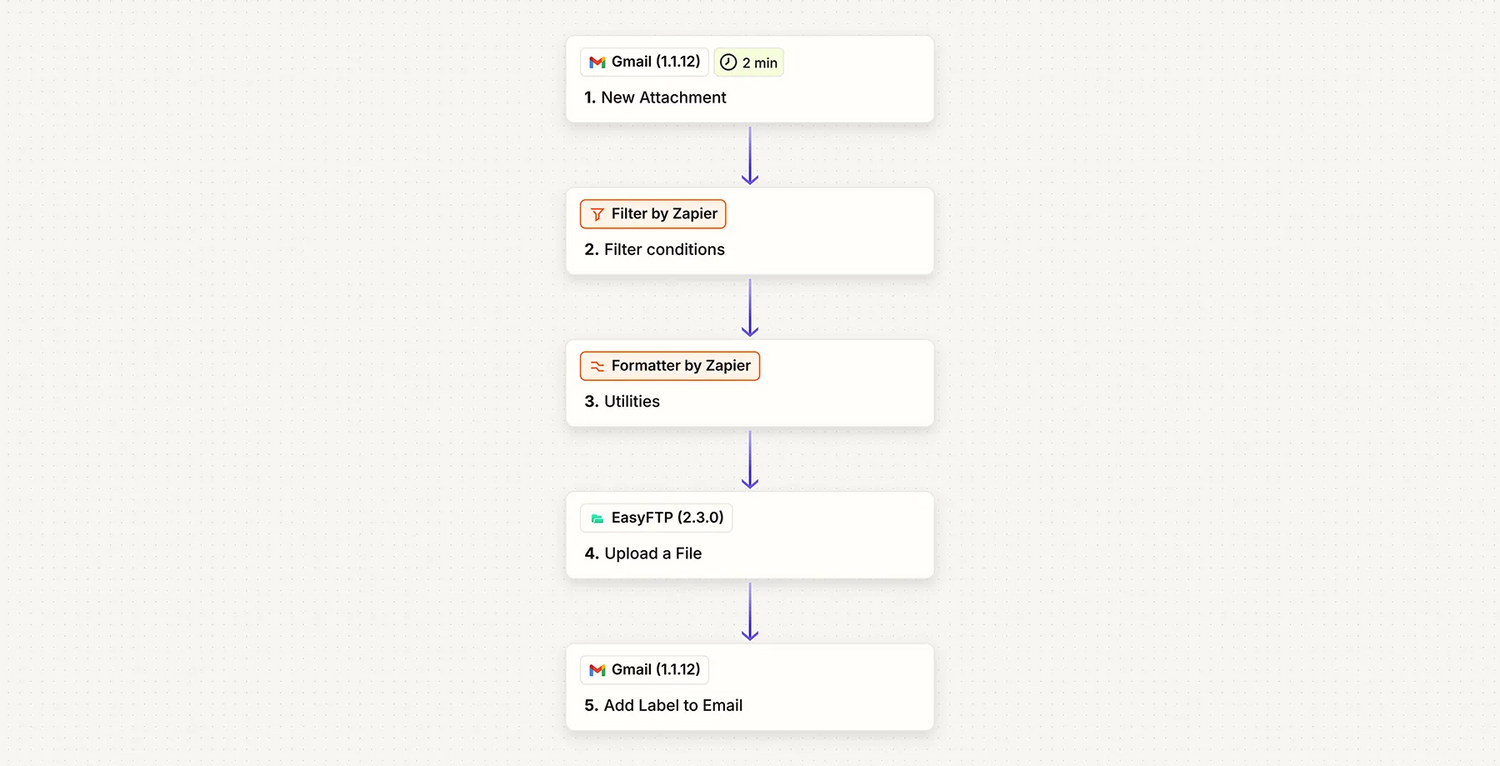

Our Solution

Results That Moved the Needle

$4700

per month in labour cost saved.

Time

Countless hours have been returned to the client allowing them to focus on customer service

Refunds

No more inventory errors leading to refunds

Results

Reach Your Goals & Reclaim Your Time

Let us help you scale while freeing up your time.